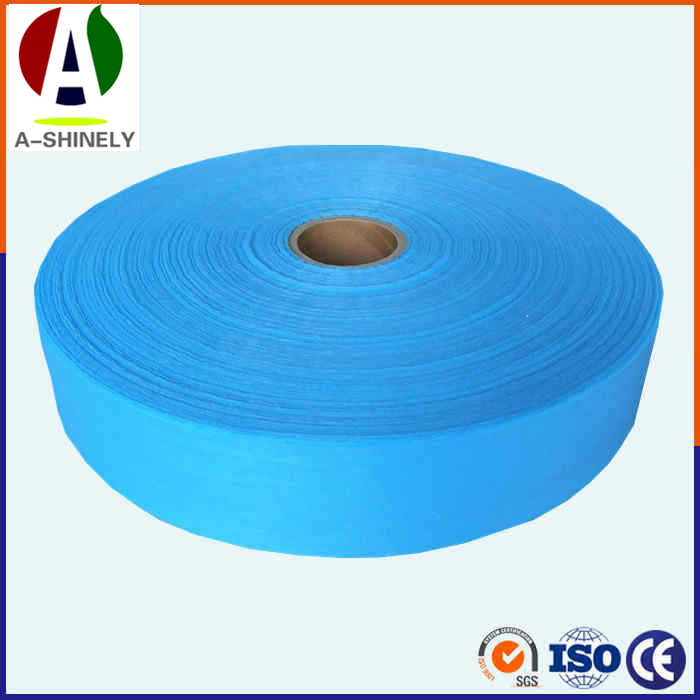

Soft And Fluffy Acquisition Layer For Diaper

The Importance of ADL Raw Materials in Baby Diapers

ADL is a sub layer used between the top sheet and the absorbent core as baby diaper raw materials. Sometimes ADL is used in full length but mostly preferred as a patch near the target zone where urine is most likely to be deposited. This sub layer--ADL is specially needed when the absorbent core is very thin -the sub layer quickly moves liquids into the absorbent core and reduces potential leakage. The ADL is very important to provide a sense of dryness to the skin, providing additional separation between the wet pad and the skin.

Specification

|

Type: |

Hydrophilic Nonwoven fabric |

|

Material: |

100% Polypropylene |

|

Nonwoven Technics: |

Hot air through |

|

Width: |

Regular 60-80mm or as your requirement |

|

Weight: |

Regulaer 15-50gsm or according your requirement. |

|

Tensile strength (MD) |

21-35N/5 cm |

|

Tensile strength (CD) |

3.5-12N/5 cm |

|

Elongation (MD) |

15-70% |

|

Elongation (CD) |

30-90% |

|

Normal strike-through time |

<3 sec. |

|

Feature: |

Mothproof,Eco-Friendly,Breathable,Anti-Bacteria,Anti-Pull,Tear-Resistant,Fusible,Shrink-Resistant,non-toxic,non-irritating |

|

Usage |

The ADL of Baby Diaper/ Adult Diaper |

|

Application |

1.Disposable personal health care products |

|

2.Women's sanitary napkins, sanitary pads, baby diaper, adult diaper,adult incontinence. |

|

|

3.Disposable medical protection products |

|

|

4.Surgical coat, cap, shoe cover |

|

|

5.Industry protection products |

|

|

Packing |

Roll with paper tube in the polybag,or according your requirement. |